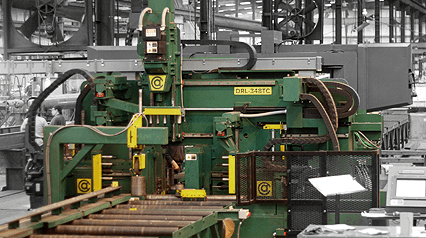

Controlled Automation DRL-348TC

The DRL-348TC is our most versatile drill system with a 5-station automated tool changer on each of the 3 spindles for flexibility of operation on parts with more than one hole size. Each 20 hp variable speed spindle has our servo ball screw feed technology. It is constructed of a rigid plate steel box frame giving it the strength to handle the heaviest of beams. Our unsurpassed X-probe measuring system ensures you have EXACT measurement on the length of your material.

Features:

- High-speed carbide drilling

- Simultaneous multi-axis drilling

- Thru-spindle coolant system

- Soft Touch Material Sensing®

- Bit Breakthrough Technology®

- Overthrust Protection®

- Advanced Angle Feed

- Control Simplicity

- Editable Drill Tool Database for all types of drill tooling

- Controlled Automation’s SICAM operating software®

- Automatic web location gaging & web depth hole compensation

Controlled Automation DRL-348TC

| Technical Data | |

| Minimum Material Width | 4 in |

| Maximum Material Width | 48 in |

| Minimum Material Height | |

| Maximum Material Height | 18 in |

| Maximum Hole Size |

2-1/4 in |

| Maximum Material Weight | 1,000 lb/ft |

| Maximum Feed Speed | |

| Power | 20 hp |

| Machine Weight | 30,000 lb + |

| Machine Dimensions (L x W x H) | |

Structual Machinery Solutions

Maximizing your ROI

Call us today

1-800-TALK-SAW (825-5729)

or